In the current era where industrial intelligence and green energy efficiency have become mainstream trends, permanent magnet synchronous motors (PMSMs) have gradually replaced traditional motors as the preferred choice for powering numerous devices, thanks to their core advantages of high efficiency, energy saving, and stability. However, many users tend to fall into the misconception of "higher parameters are better" and "blindly following the trend to choose high-end products" when selecting models. In fact, the key to selection lies in "precise adaptation" - different working conditions and equipment have vastly different requirements for motors. Choosing the right one can achieve cost reduction and efficiency improvement, while choosing the wrong one may result in performance waste or frequent malfunctions. Below, we will start with the core logic of selection, core adaptation scenarios, and key points to avoid pitfalls, to help you quickly find the suitable PMSM for yourself.

Part One: The Three Core Principles of Motor Power Selection

The essence of selection is achieving a "precise balance between demand and performance." Adhere firmly to the following three principles to avoid arbitrary decisions:

1. Functional Principle: Align with Core Operational Requirements

The core requirement is that the motor's output characteristics (power, speed, torque) perfectly match the equipment's operating conditions. Different equipment have vastly different load characteristics. For instance, lifting equipment requires high starting torque, fans and pumps need to adapt to a wide speed regulation range, and CNC machine tools have stringent demands for power stability and speed control precision. Only by ensuring the motor's performance covers the equipment's core operational needs can normal operation be guaranteed.

2. Economic Principle: Optimize Total Life Cycle Cost

Selection must consider the total life cycle cost, not just the purchase price. Prioritize motors with high energy efficiency classes (e.g., IE3/IE4 standards). While these motors may have a slightly higher initial cost, each efficiency class improvement can yield 5%-15% annual electricity savings, offering significant long-term cost-effectiveness. Simultaneously, consider maintenance costs. For example, continuously running equipment can utilize motors with maintenance-free sealed bearings to reduce subsequent upkeep.

3. Compatibility Principle: Adapt to Environment and Installation Conditions

Motor power selection must be compatible with the on-site environment and installation constraints. High-temperature environments (e.g., near boilers) require heat-resistant motors (temperature rise class F/H) with additional power margin to offset performance degradation. Damp or dusty environments require higher ingress protection (IP55 and above). Explosive atmospheres mandate the use of certified explosion-proof motors (e.g., ExdⅡBT4). Additionally, factors like installation space, supply voltage (3-phase 380V / single-phase 220V), and frequency (50Hz/60Hz) must be matched.

Part Two: Practical Steps for Motor Power Selection (with Formulas)

Scientific selection follows the logical process of "Analyzing Requirements → Calculating Parameters → Matching Type → Verifying & Optimizing." Each step must be implemented accurately.

1. Precisely Define Operational Requirements

Operating conditions are the foundation. Clarify these three core aspects:

◦ Load Type: Distinguish between constant torque loads (conveyors, mixers—torque independent of speed), constant power loads (machine tool spindles—constant power, torque inversely proportional to speed), and variable torque loads (fans, pumps—torque proportional to the square of speed). Power calculation logic differs significantly.

◦ Operating Parameters: Determine equipment rated speed (r/min), required maximum load torque (N·m), duty cycle (continuous/intermittent), and starting frequency (frequent starts require considering inrush current impact).

◦ Special Requirements: Identify needs for speed control (variable frequency drive / electromagnetic), braking (dynamic/mechanical braking), and specific requirements for ingress protection, noise, and vibration.

2. Core Parameter Calculation (Key Formula Application)

Use operational parameters to calculate the theoretical required power via formulas, avoiding "underpowering" or "over-engineering."

◦ Core Power Formula: P (kW) = T (N·m) × n (r/min) / (9550 × η)

◦ Formula Notes: T is load torque, n is rated speed, 9550 is a fixed conversion factor, η is transmission efficiency (0.85-0.95 for gear drives, 0.75-0.85 for belt drives).

◦ Supplementary Verification Points:

▪ Starting Torque Check: For frequent or heavy-duty starts, motor starting torque must be ≥ 1.2 times the load torque (induction motor starting torque is typically 1.5-2.5 times rated torque; if insufficient, consider wound-rotor induction motors).

▪ Power Margin: Account for transmission losses, load fluctuations, and environmental factors. Apply a safety factor of 1.2-2.0 to the theoretical calculation (1.2-1.5 for standard conditions, 1.5-2.0 for impact loads or harsh environments).

▪ Speed Matching: Prefer motors whose rated speed matches the equipment's. For speed control, induction motors with VFDs typically regulate from 50-1500 r/min, while servo motors offer higher precision.

3. Match Motor Type and Power Rating

Different motor types suit different scenarios. First determine the type, then select the corresponding power rating.

◦ Three-Phase Induction Motors: Simple, low-cost, easy maintenance. Power range 0.75-300kW. Suitable for conveyors, fans, pumps, etc.

◦ DC Motors: Excellent speed control, starting torque 2-3 times rated. Suitable for electric vehicles, precision winding systems.

◦ Servo Motors: High control precision (±0.01°), strong overload capacity (instantaneous 3-5 times rated torque). Suitable for CNC machines, industrial robots.

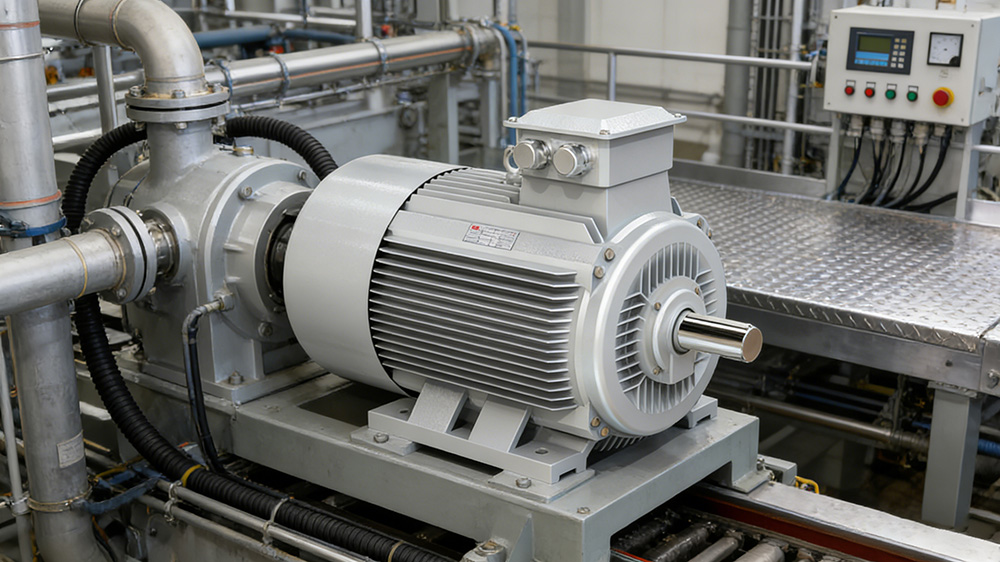

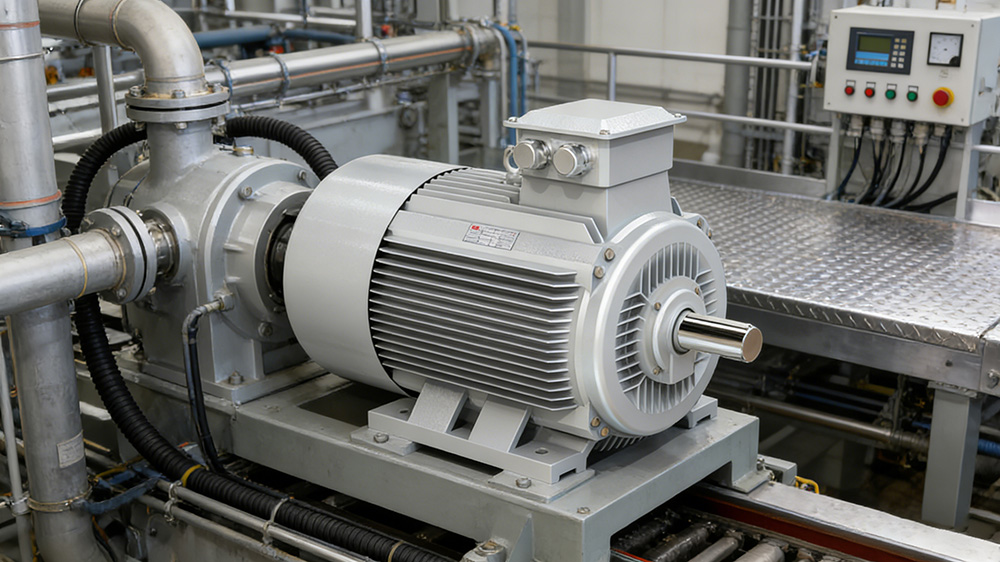

◦ ermanent Magnet Synchronous Motors: High efficiency (>95%), high power factor. Suitable for new energy vehicles, inverter air conditioners.

After type selection, use the result of "Theoretical Power × Safety Factor" to choose the closest standard power rating (e.g., 0.75kW, 1.5kW, 2.2kW, 3kW, 5.5kW), avoiding non-standard ratings for easier procurement and maintenance.

4. Verification and Optimization

Finally, conduct three verifications: 1) Thermal Verification: Ensure motor temperature rise under rated conditions doesn't exceed limits (e.g., 105K for Class F insulation). 2) Economic Verification: Calculate energy consumption and maintenance costs to confirm optimal lifecycle cost. 3) Reliability Verification: Review insulation class, bearing type, etc., to estimate if service life meets equipment requirements.

Part Three: Common Selection Pitfalls and How to Avoid Them

Many errors stem from misunderstanding core logic. Avoid these four major pitfalls:

1. "Higher Power is Always Better"

Some believe "higher power is safer," but this leads to significant waste. Oversized motors running under light load have reduced efficiency and power factor, increasing energy consumption and procurement cost.

◦ Avoidance: Calculate strictly based on conditions, follow the "just enough" principle, and only include a reasonable safety margin.

2. Focusing Only on Power, Ignoring Torque

A motor's core driving capability depends on torque, not just power. For example, a 2.2kW and a 3kW motor differ by 0.8kW, but the 3kW motor has higher starting torque, better for heavy-duty starts. Matching by power alone may cause starting difficulties.

◦ Avoidance: First calculate power based on load torque, then verify if starting torque meets requirements.

3. Neglecting Transmission Efficiency

Failing to account for efficiency losses in couplings, belts, gearboxes, etc., and selecting based solely on load power, leads to insufficient actual motor output.

◦ Avoidance: Always include transmission efficiency in power calculations and reserve an additional 10%-20% power margin.

4. Disregarding Environmental Impact

Using standard motors in harsh environments (high temp, humidity, dust) without a power margin causes rapid performance degradation.

◦ Avoidance: Select specialized motors (heat-resistant, explosion-proof, waterproof) based on environment and appropriately increase the safety factor.

Motor power selection is not about "the bigger, the better," but a process of "precise matching." The core logic is: based on operational requirements, calculate theoretical power using scientific formulas, add a reasonable safety margin, match with a suitable motor type and power rating, and finally optimize the selection through thermal, economic, and reliability verification. By avoiding common pitfalls and following the practical steps of "Analyzing Requirements → Calculating Parameters → Matching Type → Verifying & Optimizing," you can select a motor power that meets operational needs while balancing economy and stability.

Hengda Motor has long been dedicated to the R&D, production, and service of various motors. With advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable professional motor solutions, creating greater social value.