The permanent magnet motor on the production line suddenly "went on strike", and engineers repeatedly checked but could not find the reason - it is likely that the working conditions you did not pay attention to are quietly "stealing" the magnetic properties of the motor. The seemingly indestructible permanent magnet actually hides a fatal weakness. Today, we will uncover the demagnetization truth that permanent magnet motor manufacturers are unwilling to disclose.

The instantaneous demagnetization of permanent magnet motors is mainly related to working conditions such as temperature, magnetic field, and mechanical stress. Here is a specific introduction:

1. High temperature: Permanent magnet materials are very sensitive to temperature, such as common neodymium iron boron permanent magnet materials. When the temperature approaches or exceeds its Curie temperature, the magnetic properties of the magnet will significantly decrease, leading to irreversible demagnetization. Long term overload operation of the motor can cause internal heat accumulation or poor heat dissipation, which can lead to high temperatures and increased demagnetization risks. Furthermore, even if the temperature does not reach an extremely high value, the cumulative effect of long-term temperature fluctuations can lead to a gradual decline in magnetic properties, resulting in partial demagnetization.

2. Reverse magnetic field interference: The current of the stator winding will generate an alternating magnetic field. If the strength of this magnetic field is large enough and the direction is opposite to the magnetization direction of the magnet, it may cause partial or complete demagnetization of the magnet. At the same time, if there are other strong magnetic field sources in the operating environment of the motor, such as other motors, transformers, etc., these external magnetic fields may interfere with the rotor magnets, causing some magnetic domains to flip and trigger demagnetization.

3. Excessive mechanical stress: If the magnet is subjected to significant mechanical stress during installation, such as compression or bending, or if the motor is subjected to strong impact during operation, it may cause cracks or microstructural damage inside the magnet, leading to demagnetization. In addition, long-term vibration during the operation of the motor can also cause changes in the internal microstructure of the magnet, gradually reducing its performance and leading to demagnetization.

Once the permanent magnet motor is demagnetized, it can reduce efficiency and increase energy consumption, and in severe cases, it can be directly scrapped, causing huge losses to production. These hidden "demagnetization killers" in daily working conditions are not only pain points that the industry does not want to talk about, but also risks that every user must be vigilant about. Only by understanding these secrets can one truly master the password for using permanent magnet motors and keep the equipment away from the threat of sudden malfunctions.

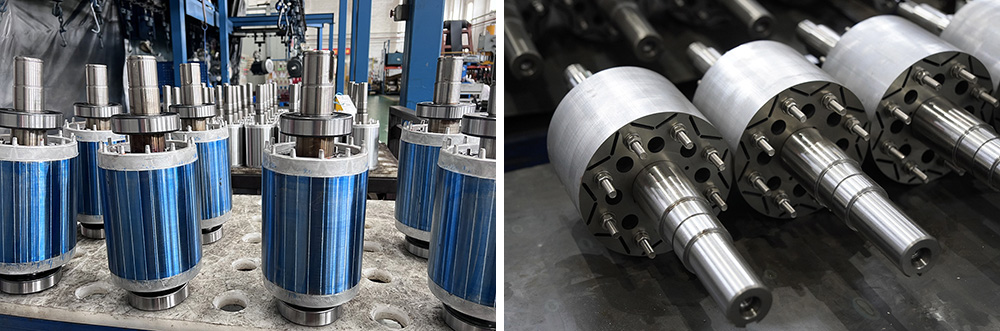

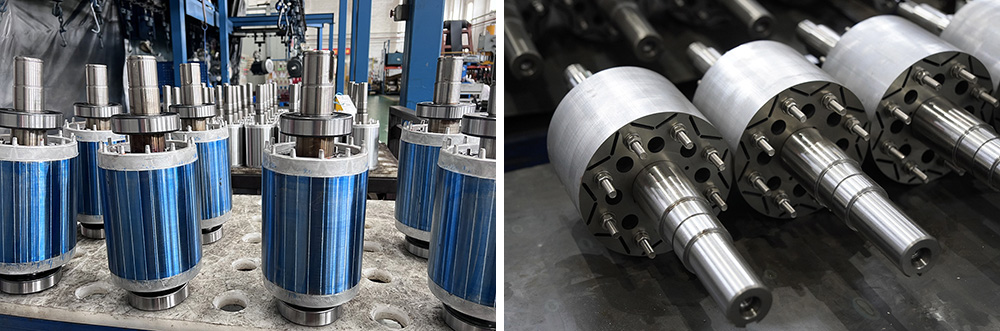

Hengda Electric has always been dedicated to the research and development, production, and service of permanent magnet motors. With advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable motor professional solutions and creates greater social value.