Permanent magnet direct drive motor is an efficient and energy-saving motor structure, widely used in many fields. This article will introduce how to further improve the energy-saving effect of permanent magnet direct drive motors.

1、Optimize motor design

During the motor design phase, the following measures can be taken to improve the energy-saving performance of permanent magnet direct drive motors:

1. Optimizing magnetic circuit structure: By designing the magnetic circuit structure of the motor reasonably, the magnetic resistance and leakage are reduced, and the magnetic field utilization rate is improved, thereby reducing the iron loss of the motor.

2. Reducing iron and copper losses: Choosing high-performance electrical materials, such as low loss silicon steel sheets and high conductivity copper wires, can reduce the iron and copper losses of the motor.

3. Improve the material quality of the rotor and stator: Select high-quality rotor and stator materials, such as high permeability silicon steel sheets and high-temperature resistant insulation materials, to reduce motor losses.

2、Using high-efficiency magnetic materials

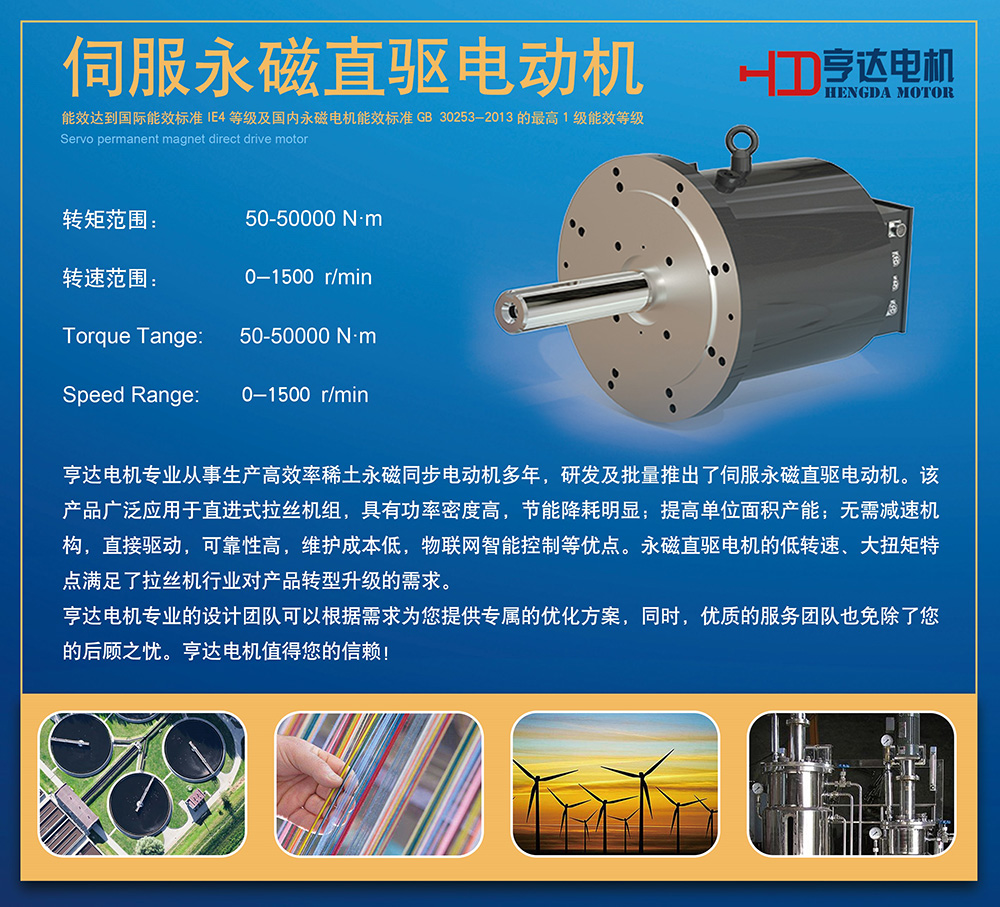

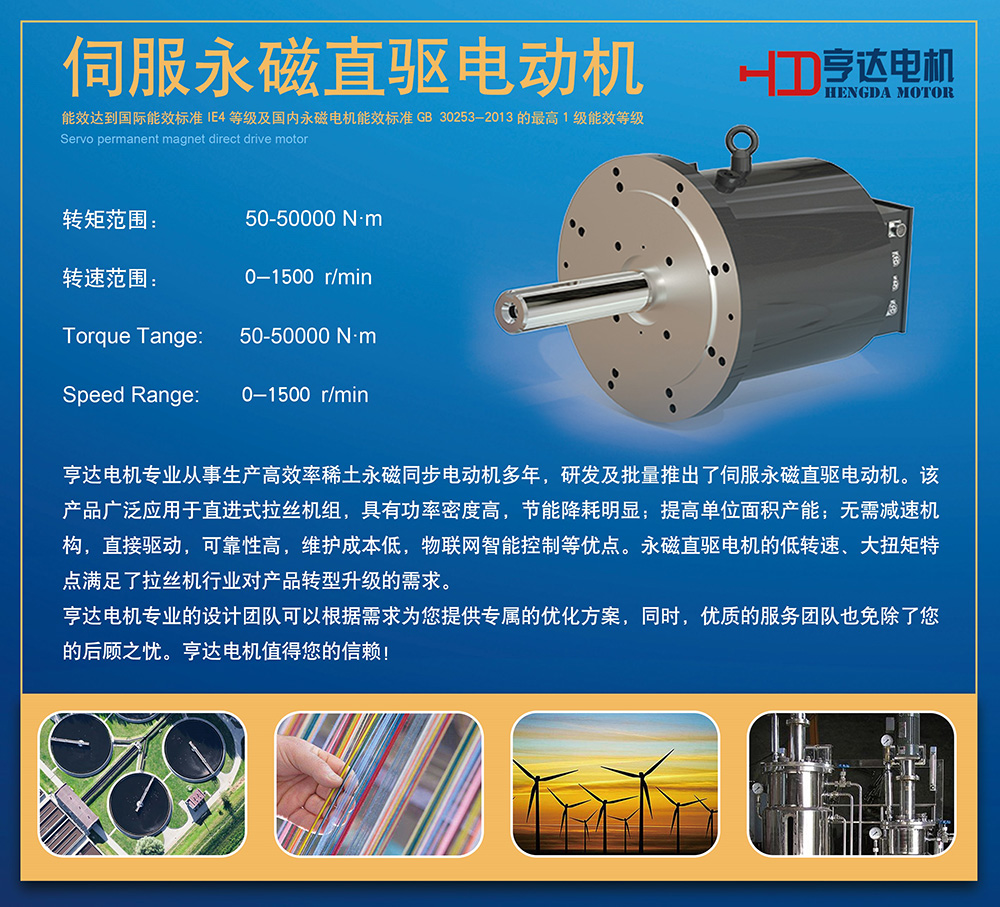

The core of a permanent magnet direct drive motor is a permanent magnet. Choosing high-performance permanent magnet materials, such as rare earth permanent magnets, can improve the magnetic field strength and thermal stability of the motor, thereby improving its efficiency. In addition, the shape and structure of the permanent magnet should be designed reasonably to maximize the utilization of magnetic field lines and further improve the energy efficiency of the motor.

3、Control strategy optimization

The use of advanced motor control algorithms can improve the energy-saving performance of permanent magnet direct drive motors:

1. Vector control: The use of vector control algorithms can achieve precise control of the motor and reduce energy loss. By accurately measuring the rotor position and speed of the motor, the control system can adjust for different load conditions to ensure that the motor operates at the optimal operating point.

2. Senseless control: Senseless control technology can achieve efficient control of motors while avoiding energy loss caused by traditional position sensors. This control method can improve the response speed and energy efficiency of the motor.

4、Efficient frequency converter

Pairing with an efficient frequency converter (motor driver) can further improve the energy efficiency of permanent magnet direct drive motors. Efficient frequency converters have high conversion efficiency and low power consumption, which can convert the electrical energy supplied by the grid into high-quality power supply for motors, reducing energy waste.

5、Load matching optimization

According to actual load requirements, match the power and speed of the motor reasonably to avoid excessive design or overload during operation. Excessive power and unnecessary speed can lead to energy waste in the motor. By accurately matching the load requirements of the motor, the operational efficiency and energy-saving performance of the motor can be improved.

6、Regular maintenance and upkeep

Regularly checking the operation status of the motor and maintaining good working conditions is the key to ensuring the efficient operation of permanent magnet direct drive motors. Regularly cleaning the dust and debris around the motor, checking the insulation status and bearing lubrication of the motor, and promptly identifying and solving problems can effectively improve the energy efficiency and lifespan of the motor.

In summary, measures such as optimizing motor design, using efficient magnetic materials, optimizing control strategies, pairing with efficient frequency converters, optimizing load matching, and regular maintenance can further improve the energy-saving effect of permanent magnet direct drive motors. These methods will help reduce energy consumption, improve energy utilization efficiency, and contribute to sustainable development.