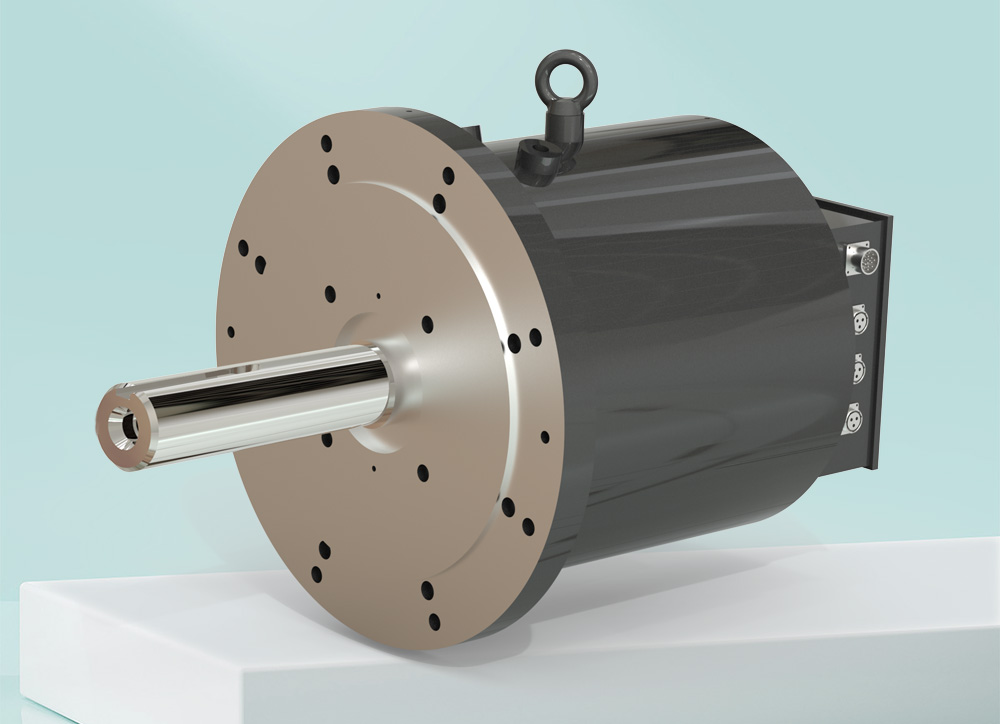

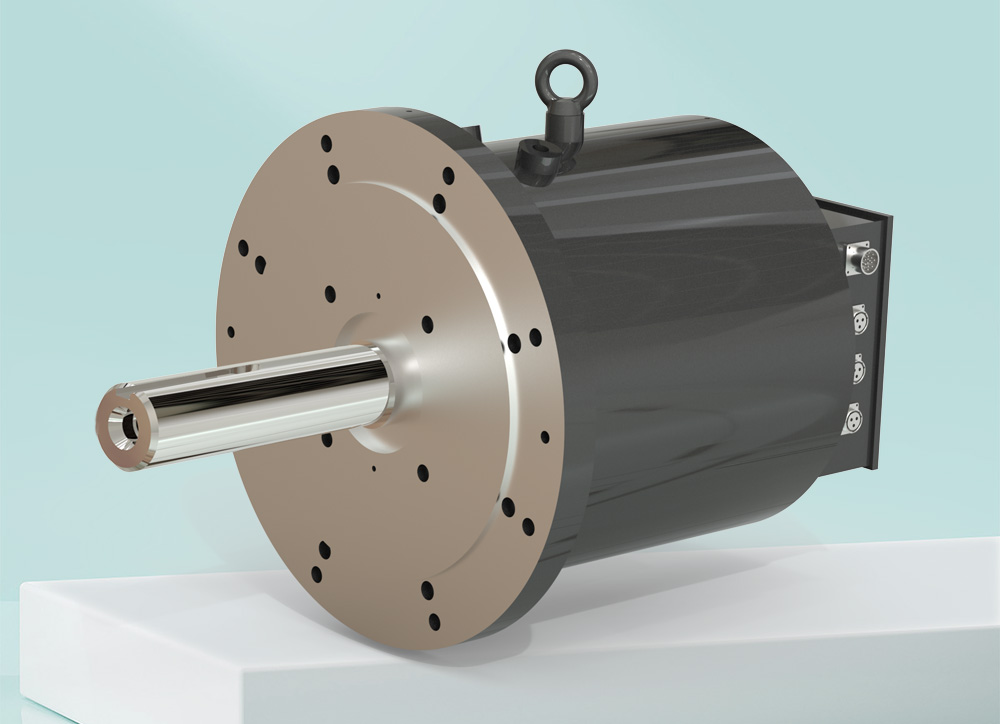

YTDD series permanent magnet servo direct drive motor is designed by Hengda for high-performance motion control. This series of motors are widely used in straight wire drawing units, with high power density, obvious energy saving and consumption reduction; Improve the production capacity per unit area; There is no need for deceleration mechanism, direct drive, high reliability, low maintenance cost, intelligent control of the Internet of Things and other advantages. The low speed and large torque characteristics of the permanent magnet direct drive motor meet the needs of the wire drawing machine industry for product transformation and upgrading.

Motor characteristics

YTDD series permanent magnet servo direct drive wire drawing machine special motor is the technical solution of maximum torque density at present, and is designed for high-performance motion control.

All motors are three-phase permanent magnet synchronous servo motors, and the rotor adopts Nd2Fe14B rare earth permanent magnet material with high magnetic energy product.

All motors have class H thermal insulation, and PT100 temperature sensor is installed in the motor to monitor the motor temperature.

All motors are designed for fluid cooling or conduction/convection cooling. For weak magnetic field operation, fluid cooling measures are required.

The stator windings of all motors are three-phase windings with vacuum impregnation paint, which can provide the best mechanical characteristics, insulation and heat dissipation performance.

The length of power supply and sensor wires provided by all motors is 1000mm, and users can put forward different length requirements. For the user's structure, power and signal connectors can also be provided.

YTDD series permanent magnet servo direct drive wire drawing machine special motor with rotary position sensor.

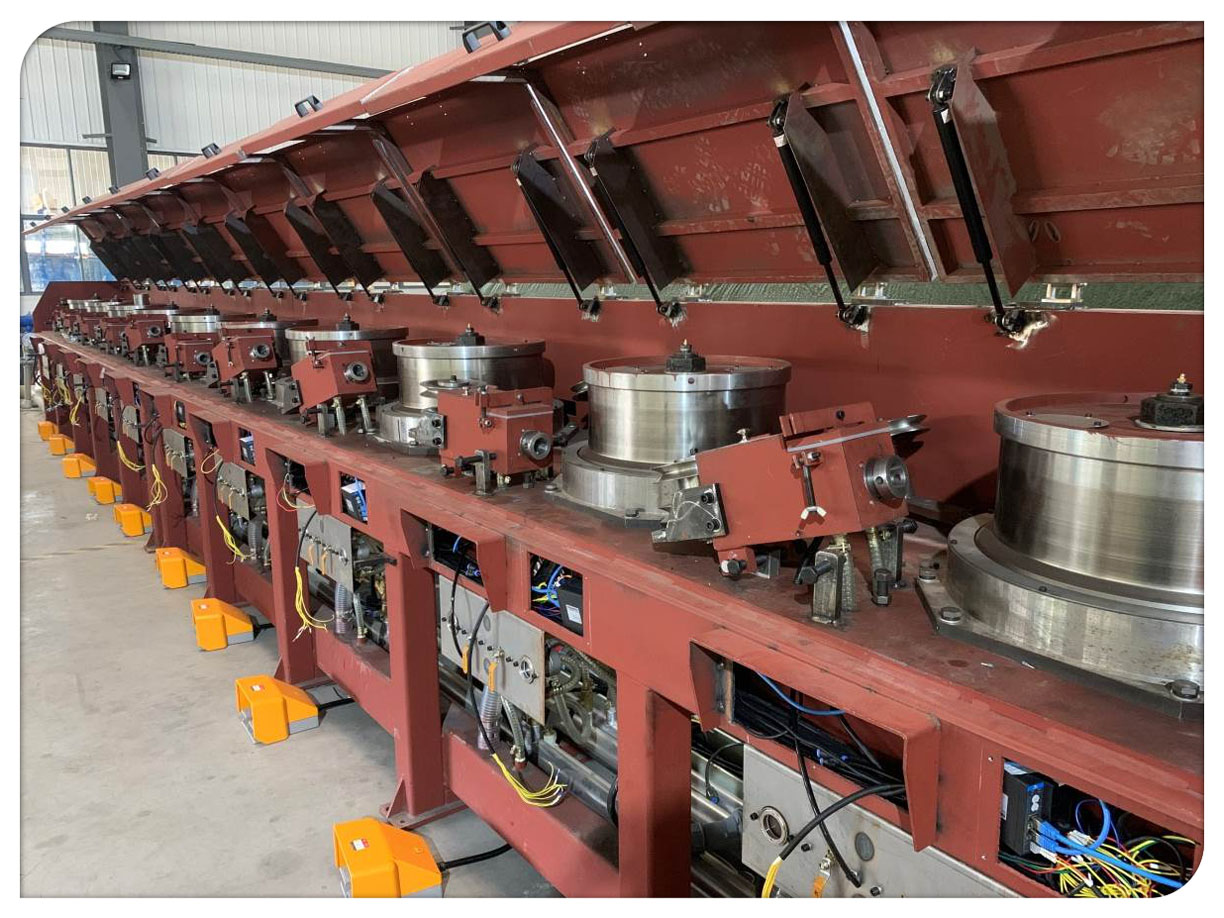

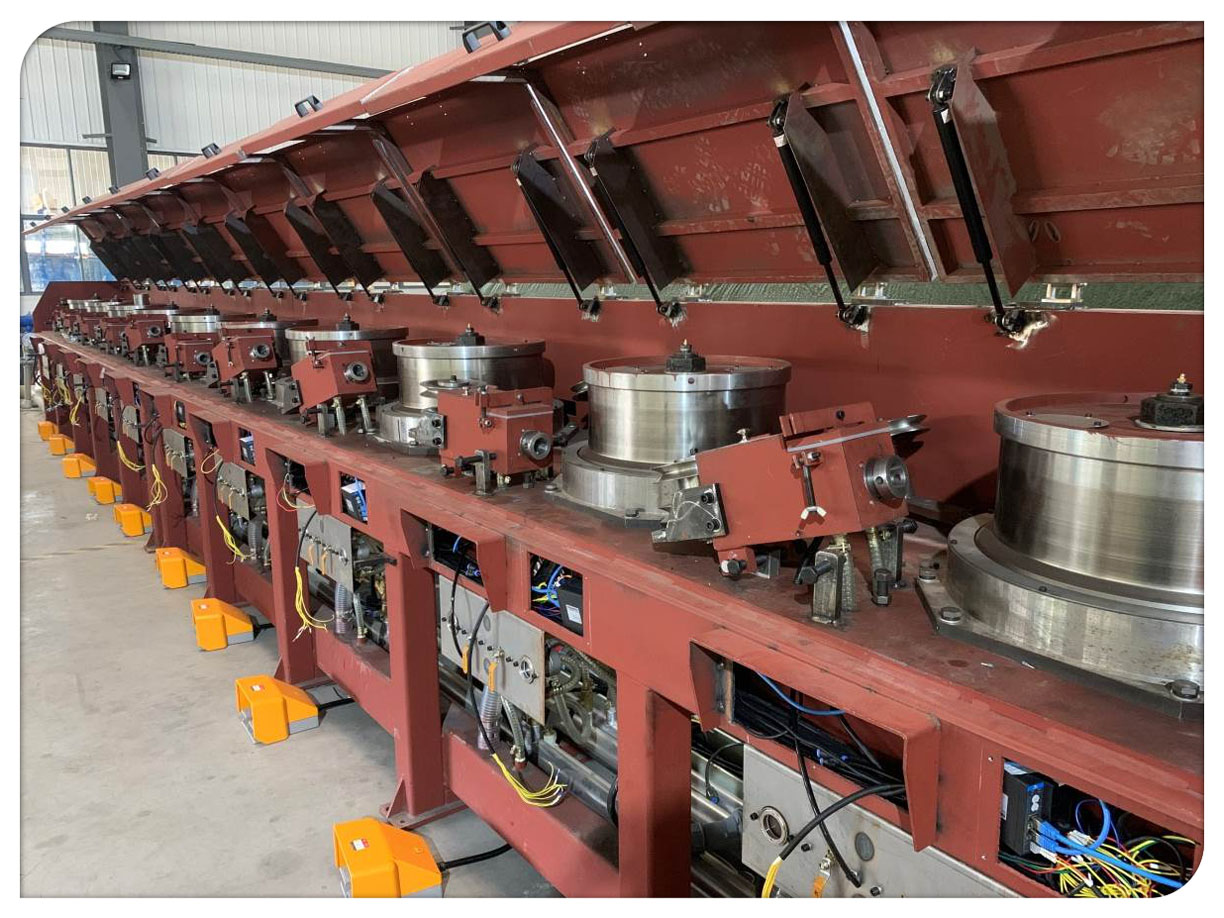

Motor application field

Wire drawing machine is a mechanical equipment widely used in industrial applications, which is widely used in machinery manufacturing, hardware processing, petrochemical, wire and cable industries.

1. Applied in the metal industry. The metal wire drawing machine belongs to the pre processing equipment for the production of metal products such as standard parts. The purpose is to draw the wire or bar produced by the steel manufacturer and transported to the metal product manufacturer such as standard parts through the wire drawing machine, so that the direct drive, roundness, internal metallographic structure, surface finish and straightness of the wire or bar can meet the raw material processing requirements for the production of metal products such as standard parts. Therefore, the pretreatment quality of wire or bar by wire drawing machine is directly related to the product quality of standard parts and other metal products manufacturers; The wire drawing machine belongs to the wire drawing machine in the metal product equipment industry. The wire drawing machine is widely used in the production and pre processing of steel wire, rope making wire, prestressed steel wire, standard parts and other metal products.

2. Wire drawing machine for copper wire processing in wire and cable industry is one of the main processing equipment in wire and cable industry. It is mainly used to process copper wire into fine wires of various specifications. It is generally composed of paying off, water-cooling, take-up, flat wire and other parts. The electrical transmission part is mainly realized by paying off motor, take-up motor and flat wire motor. With the promotion of energy conservation and environmental protection requirements, permanent magnet synchronous servo direct drive motors are increasingly used in wire drawing machines.

3. Drawing treatment of wire or bar The wire or bar of a metal product manufacturer is drawn by a wire drawing machine, so that the direct drive, roundness, internal metallographic structure, surface finish and straightness of the wire or bar meet the raw material treatment requirements for the production of standard parts and other metal products. Therefore, the pretreatment quality of wire or bar by wire drawing machine is directly related to the product quality of standard parts and other metal products manufacturers. The wire drawing machine is widely used in the production and pre processing of steel wire, rope making wire, prestressed steel wire, standard parts and other metal products.

4. Used for welding wire production. For welding wire production, the raw materials need to be processed into cylindrical ingots. The direct drive of ingots is generally 7 to 12Cm, while the welding wire is only 1mm thin. Therefore, the ingots are extruded and repeatedly drawn, and finally become finished welding wires. In the whole processing process, extruders, take-up machines, wire drawing machines and straightening machines are required. The current wire drawing machine adopts a multi-mode structure, and the structure is complex.